Hulls Engineering Australia provides pipe spooling fabrication for industrial plant setup in Melbourne using precision-built and reliable spool assemblies.

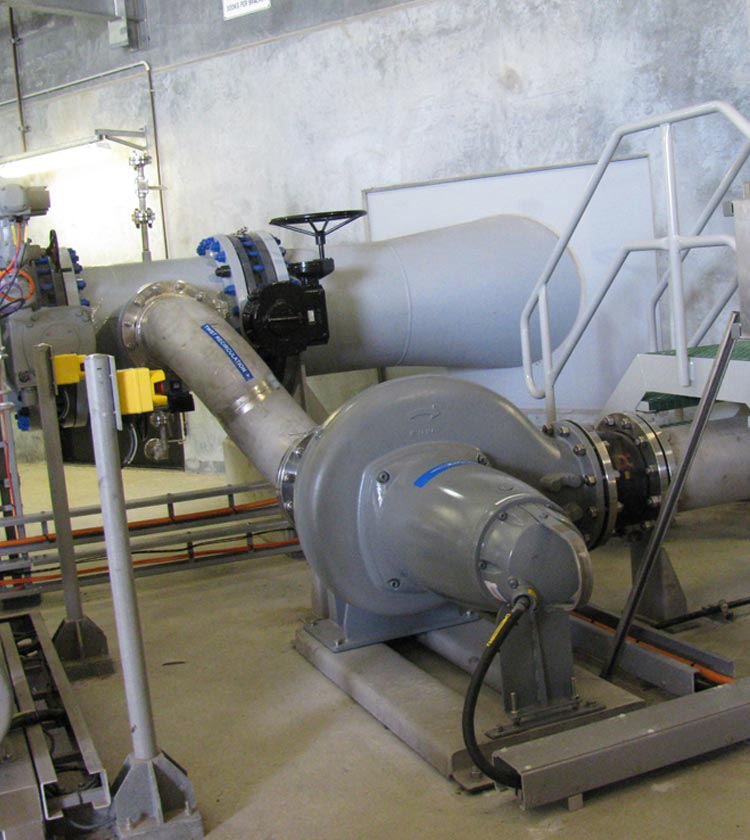

Efficient industrial construction depends on engineered components that reduce installation delays and improve workflow continuity. Pipe spooling fabrication supports this outcome by delivering preassembled spools that streamline onsite mechanical works. Hulls Engineering applies advanced fabrication methods to ensure accurate integration into critical plant infrastructure.

Pipe Spooling Fabrication Methods Supporting Reliable Installation

Specialised workshop conditions enable controlled fabrication of spooled pipe assemblies that meet tight dimensional tolerances. Every spool is produced to align with the project’s process design, ensuring components fit seamlessly during installation. Quality checks verify weld integrity, orientation accuracy and compliance with pressure, temperature and material requirements.

Plant operators benefit from predictable installation timelines once spools arrive on-site. Fabrication completed off-site reduces onsite congestion and reduces exposure to environmental limitations that slow down construction progress. Fabricated spools provide consistency across multiple system lines, supporting better project coordination and streamlined mechanical commissioning.

Ensuring Excellence in Modular Pipe Construction

Fabrication precision is essential for high-pressure systems and essential fluid conveyance infrastructure. We deploy advanced measurement technology and quality control instrumentation. This ensures every fabricated component meets strict dimensional tolerances and material specifications before its protective coating application.

Critical quality assurances in pipe spooling fabrication include:

• Following Non-destructive testing (NDT) procedures for all critical welds.

• Precise weld mapping and using full traceability documentation systems.

• Material traceability across all fittings, flanges, and piping segments.

• Adhering to hydrostatic and pneumatic pressure testing protocols.

• Conforming to all Australian and international welding codes and standards.

Streamlining Site Installation and Commissioning

Prefabricated spools are modular in nature, transforming complex, multi-weld installation sequences into simple on-site activities like lifting, positioning, and final bolting. This streamlined method minimises heavy equipment downtime and mitigates critical schedule risks, ensuring a far faster transition to full operational status compared to traditional construction.

Key technical benefits for project delivery:

• Minimised Field Welding: This reduces reliance on expensive field labour and equipment needed for time-consuming on-site joining, lowering installation costs.

• Improved Safety Profile: Performing most welding in a controlled workshop decreases personnel exposure to site-specific hazards and potential risks.

• Design Optimisation: Engineers can adjust piping layouts to enhance structural support and allow easier maintenance access.

• Faster Project Handover: Project completion accelerates by reducing punch list items related to weld quality or dimensional errors.

• Compliance Verification: Every step of the pipe spooling fabrication process is logged and validated before dispatch, simplifying final regulatory and statutory site inspections.

For further insights on piping system integrity and Australian compliance standards, see the AS 4041 Pressure Piping – WA – Australian Business Licence and Information Service.

Reliable Solutions for Industrial Plant Construction

Hulls Engineering Australia delivers dependable pipe spooling fabrication solutions that support rapid plant setup and durable system performance. Our fabrication procedures ensure each spool functions reliably within the project’s engineered tolerances and mandated safety guidelines.

Contact us for customised fabrication services that support efficient plant delivery and long-term reliability.

Related Blog Article: Stainless Tubing & Pipe Fabrication: Design Considerations to Support HACCP/GMP Compliance