Support Melbourne operations with structural steel fabrication from Hulls Engineering Australia, ensuring resilient walkways and landing solutions.

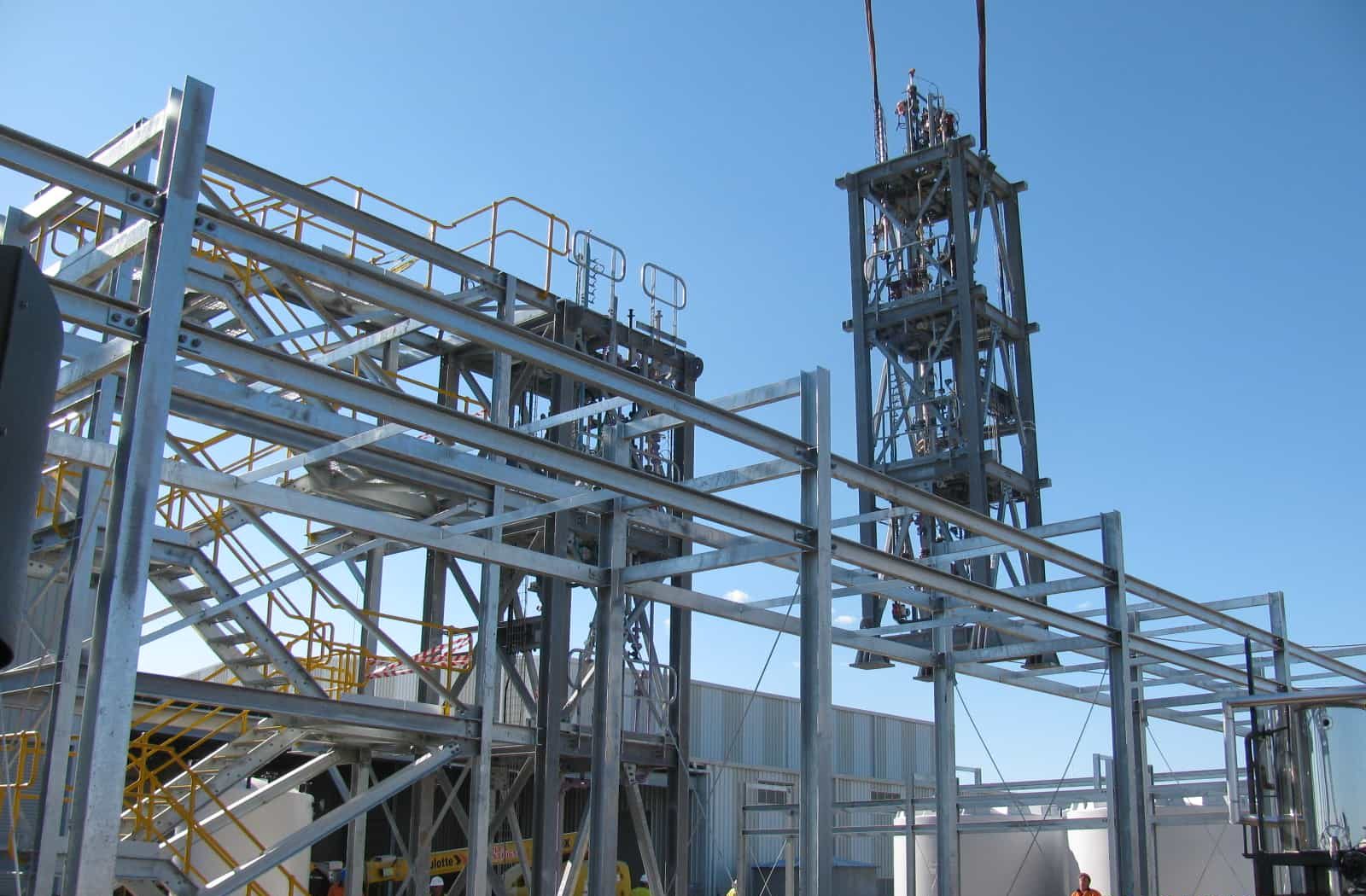

Industrial facilities require durable access systems that support safe movement, efficient operations, and compliance with Australian standards. Structural steel fabrication provides the strength and adaptability required for reliable walkways and landings in demanding environments. Access structures produced through engineered steel methods contribute to long-term stability.

Structural Steel Fabrication Requirements for Industrial Walkways

Engineered access platforms must support controlled load distribution, vibration management, and resistance to environmental exposure. These structures are designed to withstand continuous mechanical stress while maintaining stable performance across a range of facility conditions. Precision detailing, robust materials, and controlled welding methods contribute to uniform structural behaviour.

Site conditions often require assessment of wind exposure, corrosive elements, anchoring design, and integration with existing infrastructure. Properly configured access systems align with compliance codes and support predictable performance throughout daily facility activity. Dimensional accuracy and fit-for-purpose detailing maintain structural reliability.

Core Design Requirements for Safe Access Systems

Designing safe access systems requires specialised technical expertise focused on strict adherence to national benchmarks. Structural steel fabrication processes must precisely meet the requirements set out in standards like AS 1657 to ensure reliable fixed access across industrial sites.

Key safety elements include:

• Guardrail Height and Spacing: Guardrail prevents falls from exposed edges, requiring specific vertical positioning and mid-rail clearances to ensure full containment.

• Landing Load Capacity: Landings must support calculated static and dynamic loads, accommodating multiple personnel, tools, and materials without excessive deflection.

• Walkway Width: Minimum clear width standards ensure safe bi-directional traffic flow and allow for emergency passage or stretcher access if necessary.

• Tread and Riser Consistency: Stairway treads and risers must maintain uniform dimensions, eliminating trip hazards and facilitating predictable movement across various levels.

• Slip Resistance: Floor surfaces require proven anti-slip treatments, often achieved through serrated grating or chequered plate designs, especially in wet or oily environments.

Critical Factors in Walkway Material Specification

The durability of any access system relies entirely on the quality of its materials and protective finishes. Fabrication must use strong steel grades to withstand operational stress and environmental factors.

Essential material and construction considerations include:

• Galvanisation Standard: Hot dip galvanisation protects the steel from corrosion, following AS/NZS 4680 rules for maximum lifespan in Australian conditions.

• Welding Quality and Certification: Certified tradesmen must perform all welding, guaranteeing structural connections meet strength standards under AS 1554.

• Toeboard Integration: Toeboards are necessary on exposed edges to stop materials or tools from falling onto areas below, protecting staff.

• Modularity and Erection: Designing components to be modular makes on-site installation simple and reduces disruption to facility work.

• Deflection Limits: The structural steel fabrication must be engineered to comply with specific deflection limits, ensuring safe and comfortable walking even under the heaviest loads.

Industrial Access Solutions Built for Performance

Compliance is the critical deliverable in every industrial access project, requiring a specialised approach to design and manufacture.

Hulls Engineering Australia delivers advanced walkway, platform, and landing assemblies supported by stringent fabrication processes and resilient steel construction that align with industrial requirements. Our structural steel fabrication expertise ensures long-term structural reliability that meets Australian standards across diverse operating environments.

For tailored access system solutions that meet your operational standards, contact us today.

Related Blog Article: Structural Steel Fabricators Melbourne – Hulls Engineering for Safe, Precision Steelwork